Let’s get down to business

The AST® team takes a very professional approach to all requirements with regard to design, dynamic performance, functionality and quality during all stages of a project, from an enquiry right through to delivery and the after-sales service.

Our in-depth knowledge about the design and manufacture of rollers as well as our experience in the use of the most varied materials in production ensures that you will get an optimum combination of tailor-made solutions.

This is just some of what we can do for you:

Versions

- Rollers with necking, a stationary axis or single-sided bearing

- Special designs, e. g. for extremely free running or for high temperatures

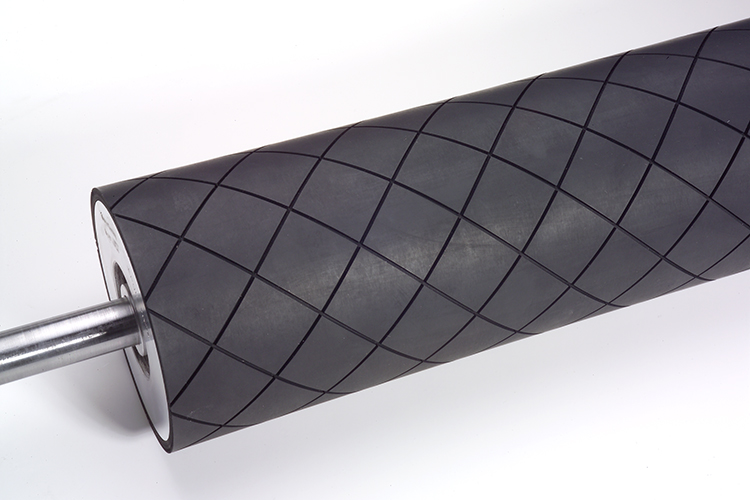

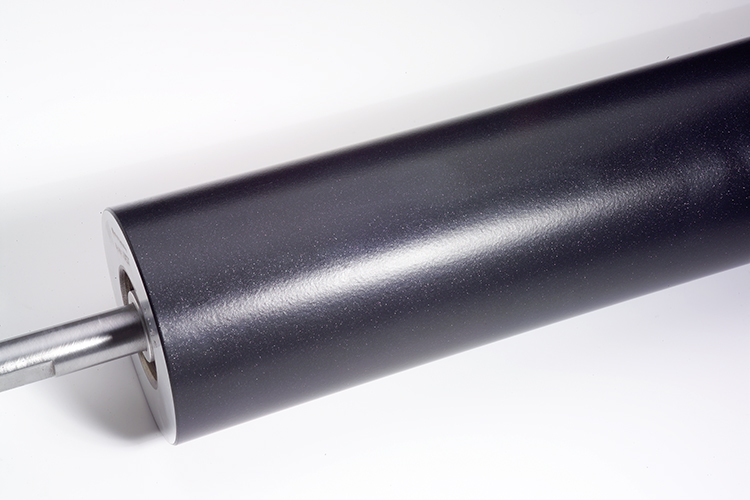

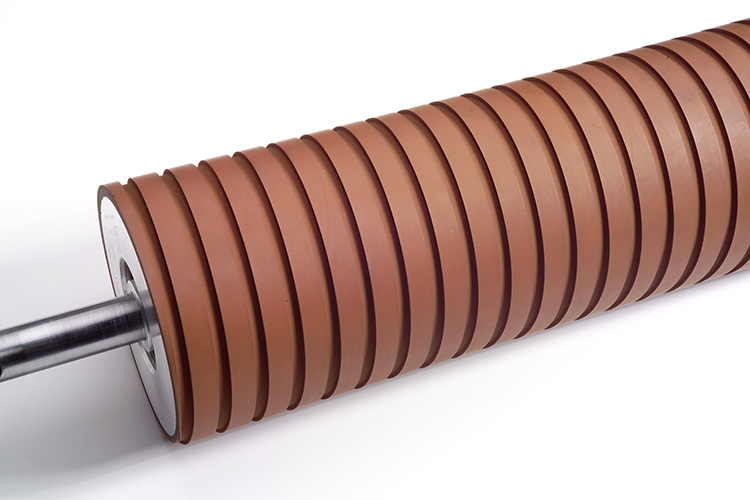

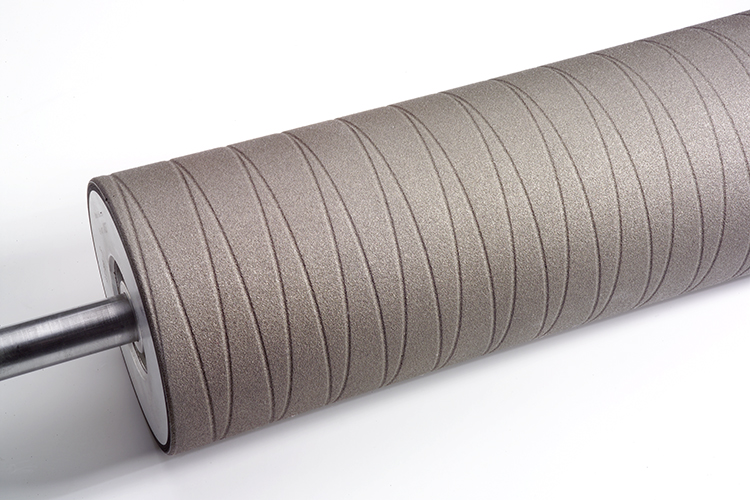

Surface textures based on specific requirements

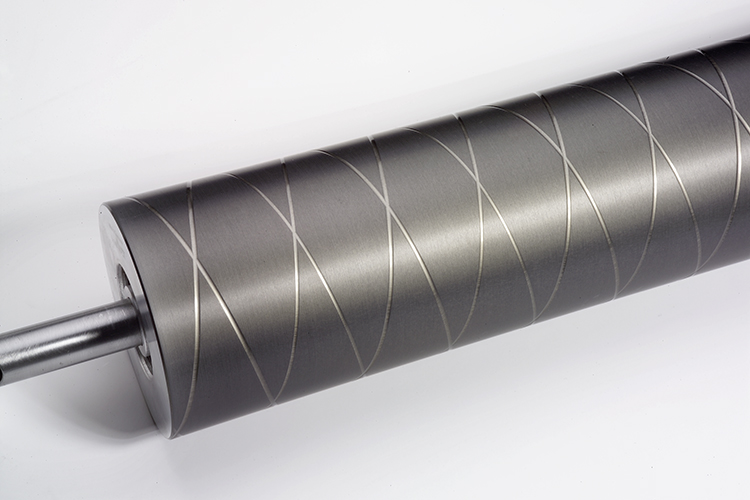

- With a spiral

- With a diamond pattern

- Finely turned

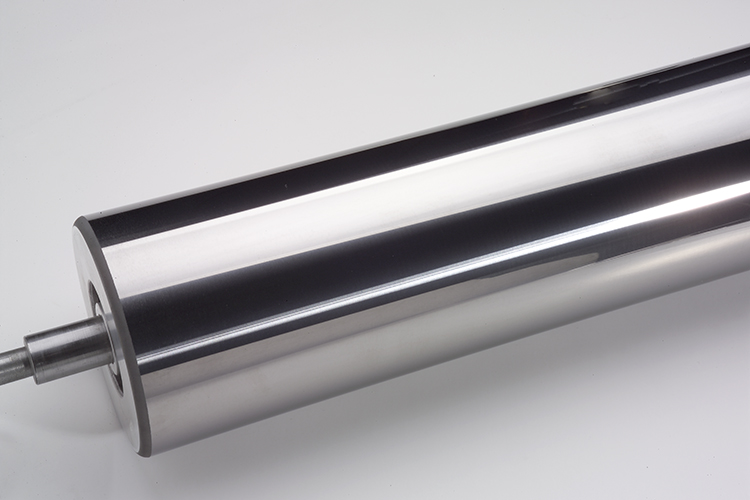

- Belt and stone-polished

- High-gloss polish

Heat treatments

- Annealing

- Hardening

- Nitriding

- Etc.

Post-processing

- Milling

- Welding

- Gluing

- Shrinking

- Aligning

Machining dimensions according to DIN ISO 1940 and 11342

| Conventionel turning | ø 300 x 6000 mm / ø 800 x 4000 mm |

| CNC turning | ø 400 x 4500 mm |

| Grinding | ø 600 x 5000 mm |

| Superfinishing | ø 600 x 5700 mm |

| Balancing | ø 1000 x 9000 mm |

Weitere Informationen zu unserem Fertigungsspektrum erhalten Sie jederzeit gern auf Anfrage.

Kontaktieren Sie uns!

Power, not downtime – productivity, not waste

Whether you want aluminium rollers with outstanding free-running properties, steel or stainless steel rollers for a high level of stability, stainless steel rollers for a high level of resistance to corrosion or CFRP/GFRP rollers that meet the most stringent rigidity, endurance limit and weight restriction requirements, our skilled employees and our seamless documentation processes ensure that we can guarantee top quality on which you can rely.

AST® rollers are all available with standard surfaces such as eloxal, rubber or chrome, or with a THERMCOAT® coating.

AST® rollers have outstanding properties:

- Smooth running at high speeds

- Low starting torques

- Very quiet running

- Narrow production tolerances

- Low breakaway torques

Our innovations for your success

At AST®, all of the rollers are developed and manufactured in-house. This puts us in the position of constantly being able to initiate product innovations. Our work results in tailor-made rollers with functional, high-precision surfaces for maximum process reliability and efficient results.

Aluminium rollers with carbide coating

Free-running rollers with a hard (>1,400 HV 0.3), very wear-resistant, cut-resistant, zero-pore and high-gloss polished surface (Rz < 0.5 μm) are a good alternative to heavy, sensitive chrome-plated steel rollers.

Steel rollers with a ceramic coating

Steel rollers with a ceramic coating, which we developed for a very corrosion-resistant surface, can replace complete stainless-steel rollers. The resistance to corrosion has been certified by a salt spray test according to DIN EN ISO 9227 lasting over 1,000 hours.

CFRP/GRP rollers with carbide coating

Composite roller with a ceramic or carbide coating impress with their very high resistance to wear with surface hardnesses in excess of 1,400 HV 0.3 and a surface finish of Rz < 1 μm.